Precision on the Road: The Structure Behind Reliable Vehicles

How Automotive Components Support Everyday Mobility

Modern vehicles operate through balance. Each movement, stop, and turn depends on parts designed with purpose. Automotive components form the working structure that allows vehicles to perform without constant attention from the driver.

These parts handle stress every day. Heat from engines, friction from braking, and vibration from roads test their limits. Engineers design components to manage these forces while keeping performance steady.

A simple example is a drive belt. It transfers motion across systems. If it slips or wears, multiple functions fail at once. This risk shows why design clarity matters.

Dependable travel starts with dependable parts.

Vehicles today also demand efficiency. Parts now aim to reduce energy loss. Smooth surfaces, tighter tolerances, and lighter materials support this goal.

Vehicle Systems Built From Automotive Components

Each vehicle system groups parts with shared tasks.

- Power delivery, control, safety, and support systems define vehicle function.

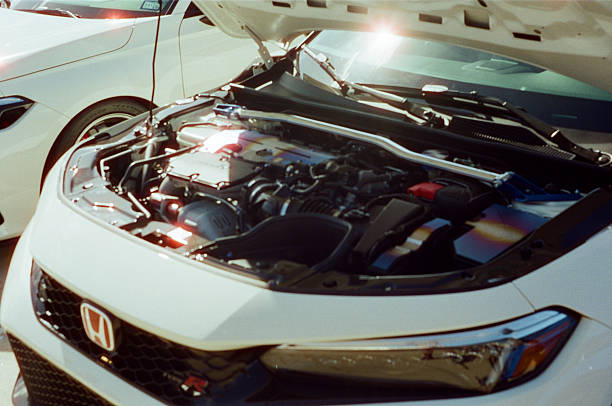

The power delivery system includes engines, motors, and transmissions. These parts convert energy into motion. Precision keeps them efficient.

Control systems guide movement. Steering racks, linkages, and sensors translate driver input into direction.

Safety systems manage risk. Brakes, airbags, and stability controls respond within seconds. Their components must work without delay.

Support systems improve comfort. Mounts, seals, and insulation reduce noise and vibration.

Example: In poor weather, braking components must clear water fast to maintain grip.

Good design prepares parts for the worst conditions.

Why Automotive Components Quality Matters

Quality affects reliability and cost. Strong materials resist wear. Accurate machining reduces friction.

Poor-quality parts often fail early. They may fit loosely or wear unevenly. This failure can damage nearby components.

Pro Tip: Choose parts that meet original specifications. Compatibility reduces stress across the system.

Examples highlight this point. A high-grade suspension bushing maintains alignment. A weak one shifts under load and affects handling.

Maintenance also becomes easier with quality parts. Fewer adjustments save time during service.

Quality parts protect the whole system.

Design Focus and Industry Direction

Design trends favor simplicity. Fewer parts reduce failure points. Modular designs allow faster repair.

Electronics now guide many systems. Sensors replace mechanical links. This change improves accuracy.

Material use continues to evolve. High-strength alloys and composites replace heavier designs. These materials support durability without added weight.

Clear labeling also improves service accuracy. Mechanics can identify parts faster and reduce errors.

Conclusion

Vehicles perform well because their parts work with discipline. Each component has a defined role. Together, they create reliable motion.

As design advances, parts will grow lighter and smarter. The goal remains steady. Support safe, efficient travel every day.